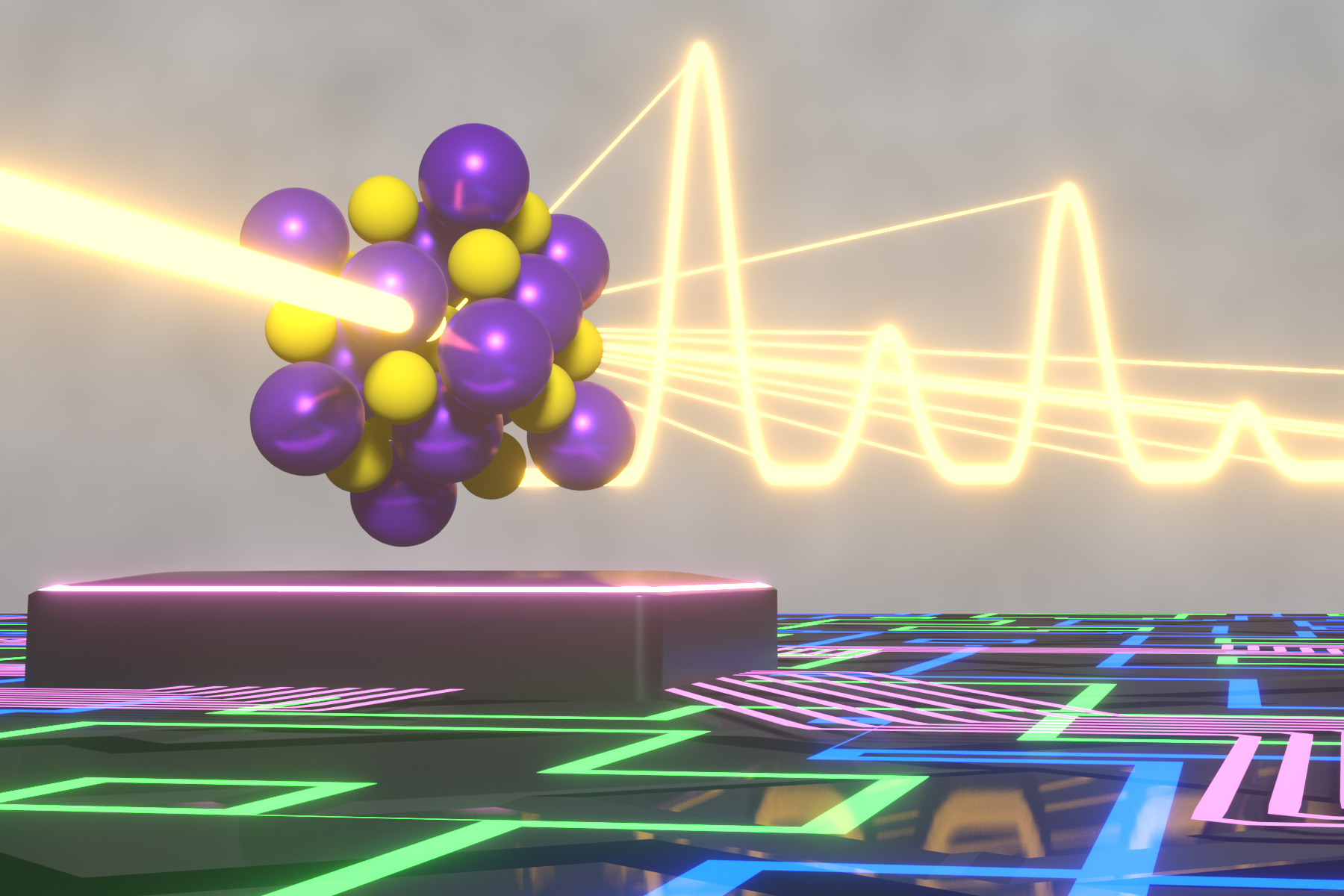

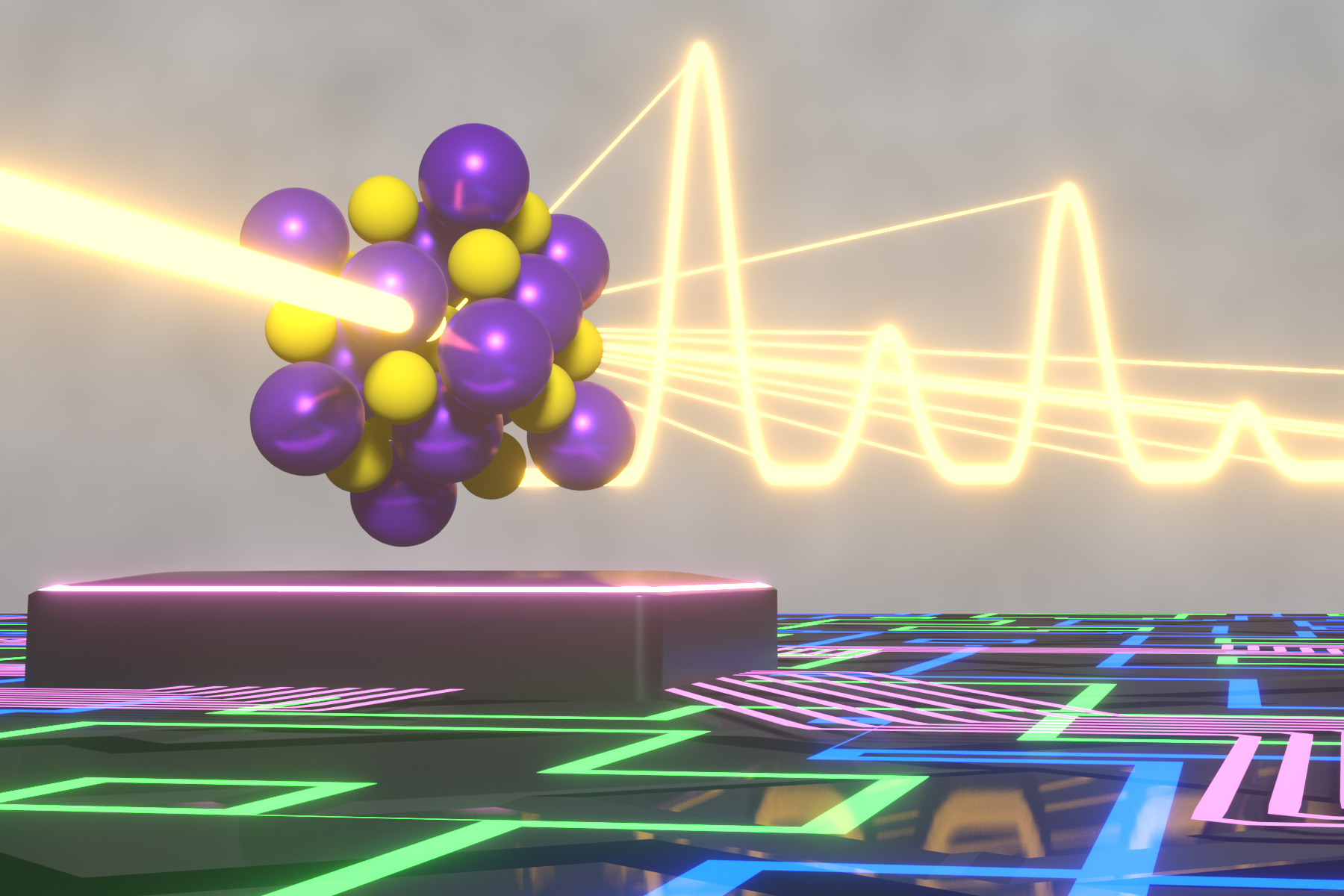

For over 100 years, scientists have used X-ray crystallography to determine the structure of crystalline materials such as metals, rocks, and ceramics.

This technique works best when the crystal is intact, but in many cases, scientists only have a powdered version of the material that contains random pieces of the crystal, making it more difficult to carve out the entire structure.

MIT chemists have now come up with a new generative AI model that can make it much easier to determine the structure of these powdered crystals. The predictive model could help researchers characterize materials for use in batteries, magnets, and many other applications.

“Structure is the first thing you need to know about any material. It’s important to know how to make superconductivity, magnets, what kind of solar cells you can make. It’s important for any application that’s materials-centric,” says Danna Freedman, the Frederick George Keyes Professor of Chemistry at MIT.

Freedman and Jure Leskovec, a computer science professor at Stanford University, are senior authors of a new study published today in the journal Journal of the American Chemical SocietyMIT graduate student Eric Riesel and Yale undergraduate Chach Makey are the paper’s lead authors.

Unique pattern

Crystalline materials, including metals and most other inorganic solids, are made up of lattices made up of many identical repeating units. These units can be thought of as “boxes” of a unique shape and size, with atoms arranged precisely inside them.

When X-rays are shone on this grating, they diffract the atoms at different angles and intensities, revealing information about the positions of the atoms and the bonds between them. Since the early 1900s, this technique has been used to analyze materials, including biological molecules with crystalline structures, such as DNA and some proteins.

For substances that exist only as crystals in powder form, unraveling these structures is much more difficult, since the fragmented crystals do not retain the complete three-dimensional structure of the original crystal.

“The exact lattice is still there, because what we call a powder is actually a collection of microcrystals, which means they have the same lattice as the larger crystals, but they are completely randomly oriented,” says Friedman.

X-ray diffraction patterns exist for thousands of these materials, but they are still unresolved. To decipher the structures of these materials, Freedman and her colleagues trained a machine learning model on data from a database called the Materials Project, which contains more than 150,000 materials. First, they fed tens of thousands of these materials into an existing model that can simulate what an X-ray diffraction pattern would look like. They then used those patterns to train an AI model called Crystalyze to predict the structure based on the X-ray pattern.

The model divides the process of predicting a structure into several subtasks. First, it determines the size and shape of the lattice “box” and the atoms that will fit inside it. Then, it predicts the arrangement of the atoms inside the box. For each diffraction pattern, the model generates several possible structures, which can be tested by feeding them into the model, which determines the diffraction pattern for a given structure.

“Our model is generative AI, which means it can generate things that it hasn’t seen before, and from that it can generate a bunch of different guesses,” Liesel said. “We can make 100 guesses, and then we can predict what the powder pattern will look like for those guesses. And then if the input is exactly the same as the output, we got it right.”

Solving the unknown structure

The researchers tested the model on thousands of simulated diffraction patterns from the Materials Project. They also tested the model on more than 100 experimental diffraction patterns from the RRUFF database, which contains powder X-ray diffraction data for about 14,000 natural crystalline minerals that they had excluded from the training data. On these data, the model was accurate about 67 percent of the time. They then began testing the model on previously unresolved diffraction patterns. These data came from the Powder Diffraction File, which contains diffraction data for more than 400,000 resolved and unresolved materials.

The researchers used their model to come up with structures for more than 100 previously unsolved patterns. They also used their model to find structures for three materials that Friedman’s lab created by forcing elements that don’t react at atmospheric pressure to form compounds at high pressure. The approach could be used to create new materials with fundamentally different crystal structures and physical properties, even if they have the same chemical composition.

Graphite and diamond are both made of pure carbon and are examples of such materials. The materials developed by Friedman each contain bismuth and one other element, and could be useful in the design of new materials for permanent magnets.

“We have discovered many new materials from existing data, but most importantly, we have solved three previously unknown structures in our lab that constitute the first new binary phases of these elemental combinations,” says Friedman.

According to the MIT team, being able to determine the structure of a crystalline material in powder form could be helpful to researchers working in almost any materials-related field. The team has posted a web interface to their model at crystalyze.org.

This research was supported by funding from the U.S. Department of Energy and the National Science Foundation.